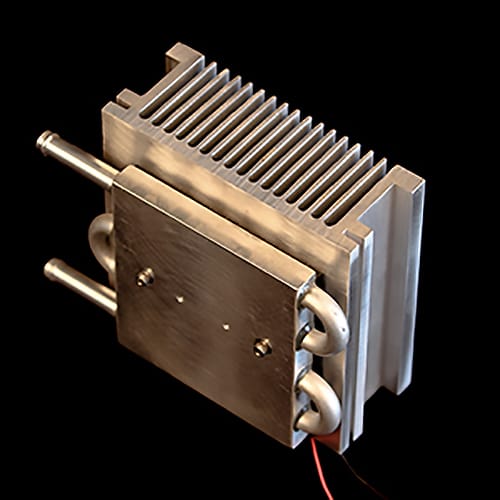

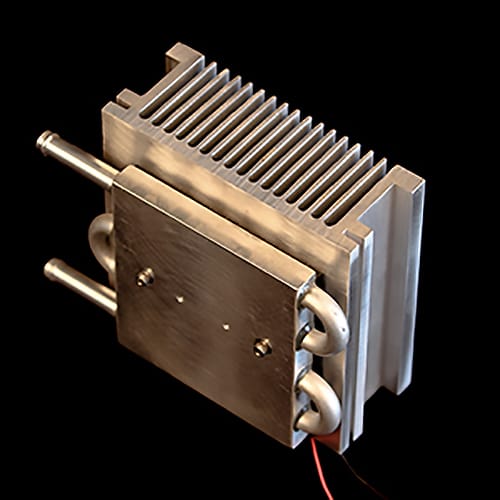

CNC Milling

Computer Numerical Control (CNC) is used by a class of machines to perform sophisticated and precise milling work. Our DMG Mori has a 5-sided/5 axis simultaneous machining feature, a powerful motor spindle with up to 18,000 RPMs, and has an integrated swivel rotary table. Our CNC machines have been validated and are capable of up to 7 axis operations. Our Haas vertical mills are capable of overall axis’ travel capabilities of 40”(X), 20”(Y) and 25”(Z). Our horizontal mills have a rapid traverse rate of 1,000”/min and a maximum cutting feed rate of 500”/min. Our GR-408 Gantry router has a 10-station tool carousel tool changer which can perform milling, drilling, engraving and tapping operations on multiple types of materials. Our Haas SR-100 open frame CNC sheet router is equipped with a 24,000 RPM ISO taper spindle for cutting and drilling various plastics, sheet metals, and other light materials. Additional CNC operations include dry machining, model vs. print, live tooling, and cell manufacturing.

METAL (PARTIAL LIST) -

MP 159, ALLOY STEEL, ALUMINUM, BRONZE, BRASS, CARBON, COPPER, MAGNESIUM, NICKEL , STAINLESS STEEL, SUPER ALLOYS, TITANIUM ALLOYS, TUNGSTEN.

PLASTIC (PARTIAL LIST) –

ABS , ACETAL, DELRIN, FEP FILM, HIGH DENSITY POLYETHYLENE, HI-IMPACT STYRENE, NITRILE, NORYL, NYLON , PEEK, PEEK FILMS, PETG, POLYCARBONATE, POLYESTER, POLYETHYLENE , POLYPROPYLENE, PVC, PVDF, PTFE, RYTON, SILICONE, TFE, TORLON, UHMW, ULTEM, VESPEL, VINYL.